Loading... Please wait...

Loading... Please wait...Our Newsletter

M-40

The M-40 Cryoguard™ Thermal Exposure Indicator

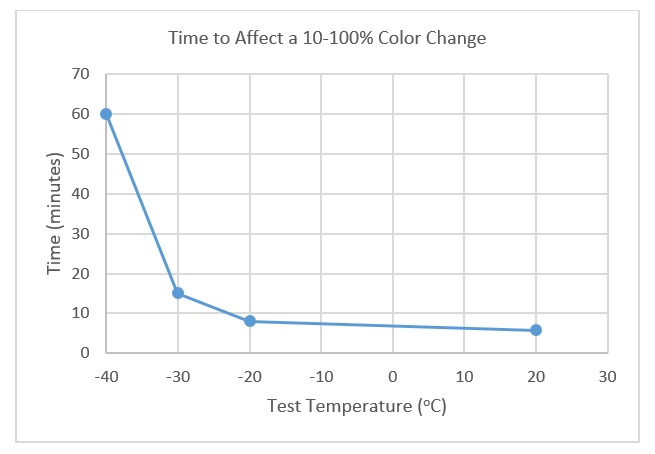

The M-40 Cryoguard Thermal Exposure Indicator signals thermal exposure at or above -40°C by irreversibly changing color from green to red. Upon transfer from an initial environment at or below -65⁰C to an environment at -40⁰C, the indicator exhibits a noticeable color change within one hour. The time to affect a color change dramatically decreases with increasing temperature, as illustrated in the figure below. At ~20⁰C, the time required to affect a color change is about 6 minutes. The distinct real-time signal allows recipients and users of perishable cryopreserved materials to verify the maintenance of cryo-environments quickly and reliably.

Product Applications

1. Continuous monitoring of frozen materials during shipping.

2. Continuous monitoring of frozen materials while being inspected by customs agents.

3. Continuous monitoring of frozen materials during storage.

4. Continuous monitoring of frozen materials during power outages when freezer control systems are not working.

5. Continuous monitoring of frozen materials during their transient removal from freezer for handling by personnel.

6. Continuous monitoring of materials in dry shippers.

7. Indicators fit inside freezer box partitions and on cryovials and freezer canes.

M-40 indicators are used at or below -65°C to continuously monitor cryopreserved materials such as heat sensitive laboratory specimens, tissues, allografts, vaccines, frozen blood plasma, bone grafts, pre-mixed epoxy resins, and heat-sensitive electronics.

Technical Specifications

What Does a Green M-40 Indicator Signify?

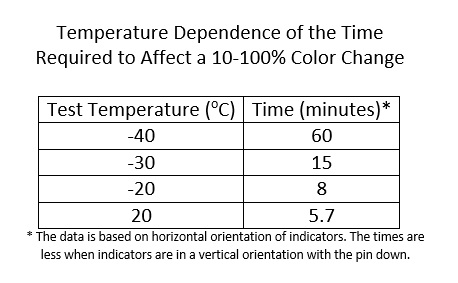

A completely green indicator (with no red or colorless regions) means that the material in the vicinity of the indicator was never at -40⁰C for more than one hour or at -30°C for more than 15 minutes or at -20°C for more than 8 minutes.

The graph below shows the time required at various test temperatures to affect a 10-100% color change, upon transfer of the M-40 indicator from an environment at or below -65°C to an environment at the plotted test temperature.

Activation of the M-40 Indicator

Click Here for a video of the activation procedure of the M-40 Indicator.

The activation process involves freezing the indicator, removing it from the cryo-environment, slowly depressing its activation pin, and immediately re-freezing the indicator to a temperature at least 25⁰C below the signal temperature. Indicators should be activated and re-frozen one at a time in order to minimize time between these two steps. After re-freezing, the indicator is ready to monitor the desired environment.

***For more detailed activation information, please visit the Activation Guide page.

Note: When handling frozen indicators, one should avoid contact with bare hands to prevent heat transfer and freeze burn.

Recommended Procedure:

-

Completely freeze the indicator. This may be done by placing it in an environment at or below -65°C for one hour, such as in dry ice.

-

Remove the indicator from the cold environment.

-

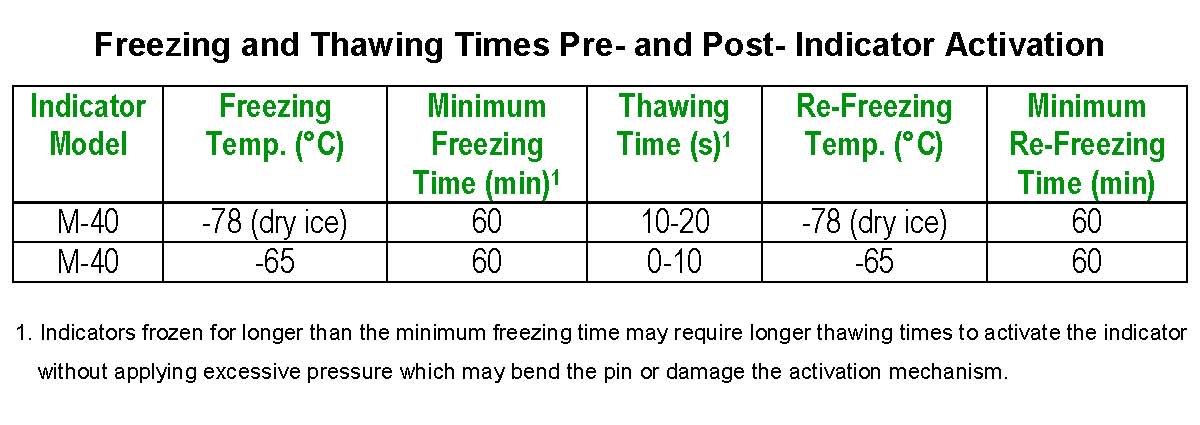

Wait 0-10 seconds if the indicator was frozen at -65°C or 10-20 seconds if it was frozen in dry ice to sufficiently thaw the indicator so that the pin can be depressed without excessive force. See table below for minimum freezing and thawing times.

-

Slowly press the activation pin into the indicator until flush with the indicator body. The pin may be depressed using channel lock pliers, our Cryoguard™ Activation Tool, or by pushing against a hard flat surface. Do not use extreme impact such as a hammer blow to depress the pin, as this can damage the activation mechanism.

-

Immediately refreeze the indicator to a temperature at or below -65°C. This prevents a premature thermal exposure signal and readies the indicator for monitoring. The indicator temperature can be rapidly lowered below -65°C by burying it in dry ice for 60 minutes.

-

Place the indicator in the environment to be monitored either on its side or in a vertical position with the label end up.

Coolant Compatibility

The indicator can be used in contact with dry ice, liquid nitrogen, liquid nitrogen vapor phase, and with frozen materials in insulated containers and mechanical freezers.

Shelf-life and Storage

Indicators are shipped ~8 months prior to their expiration date, which appears on the indicator label. Whether activated or not, indicators should not be used after the expiration date. Unactivated M-40 indicators should be stored at 15° to 30°C (e.g. at room temperature) in the dark.

Size and Packaging

Indicators are sealed in a plastic housing approximately 1" long and 0.5" in diameter. The indicator housing contains eyelets for wiring it to the monitored material. An alert label for affixing to containers monitored by the indicator is supplied with each indicator. The alert label is a 1" x 4.25" peel and stick adhesive label.

Chemical Composition

Indicator solutions have an approximate volume of 1 mL per unit and are comprised of buffered mixtures of aqueous dyes, alcohols, glycols and water. Indicators may be safely discarded as standard waste.

Quality Assurance

Several indicators in each batch are tested in a Model 7450 CryoMed Controlled Rate Freezer using NIST calibrated thermocouple thermometers to verify that the indicators in each batch perform as specified above.

Procedure for Disposing Used/Damaged/Expired Indicators

Indicators at room temperature may be discarded as standard toxic waste. To discard indicators that were stored in a cold environment, place them in a covered container at room temperature until completely thawed before disposal.

X-ray Irradiation Notice

Although Cryoguard indicators can be safely exposed to x-rays from diagnostic and security scanners, the indicators should not be exposed to ionizing x-ray radiation. Exposure to ionizing x-rays will permanently deactivate the indicator, causing it to lose its ability to signal thermal exposure. Indicators may still be used with irradiated products, after the products have been irradiated.