Loading... Please wait...

Loading... Please wait...Our Newsletter

Cold Facts Article 2016

![]()

Cryoguard™ Corporation Introduces New Thermal Exposure Indicators and Freezer Boxes

Cryoguard Corporation recently expanded the temperature range covered by their thermal exposure indicators by introducing the M-135 and M-150 thermal exposure indicators. With the development of these units, Cryoguard indicators can now signal thermal exposure at six preset signal temperatures from ‑40°C down to ‑150°C.

Cryoguard Corporation manufactures thermal exposure indicators for ensuring the quality of heat sensitive material. The indicators were first developed by the company’s founder in response to a request from US Navy scientists who wanted a sensor that could ensure the quality of blood products being shipped to the battlefield. Over the years the indicators have proved useful for ensuring the quality of a wide variety of heat sensitive materials.

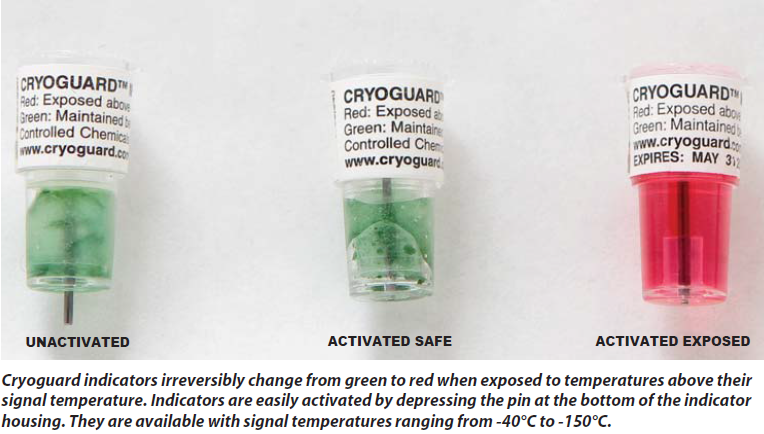

Cryoguard thermal exposure indicators signal thermal exposure with an irreversible color change from green to red and thus can provide real-time quality assurance that heat-sensitive goods are not thermally compromised. The indicators are about 0.5” in diameter and 1” long. Depressing a pin at the bottom activates the unit. Each indicator is frozen prior to use and will quickly refreeze once activated and placed in an environment to be monitored.

When kept at least 25 degrees below its signal temperature the indicator remains green. At its signal temperature, an indicator will change color within two hours. At ten degrees above its signal temperature the indicator changes color within minutes.

A green indicator provides real-time quality assurance that the monitored material is not thermally compromised and is safe to use, provided that the monitored material can tolerate two hours at the signal temperature of the indicator.

Because the M-135 and M-150 indicators have a high thermal lability, Cryoguard developed a special activation tool to avoid a premature color change during activation of the frozen M-135 and M-150 thermal exposure indicators. The tool enables quick and easy activation of all Cryoguard indicators both on and off freezer canes.

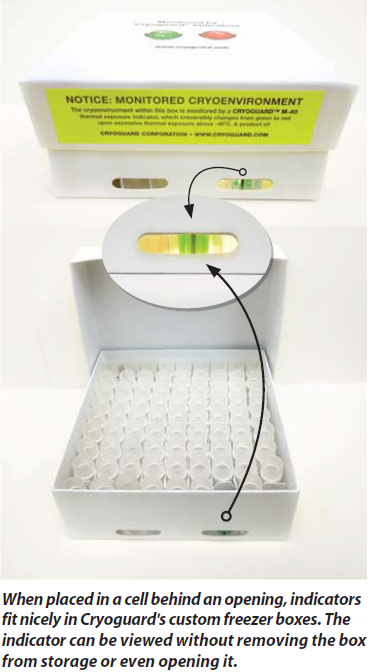

The company has also introduced new Cryoguard freezer boxes, equipped with indicators that can be viewed in covered boxes. These freezer boxes uniquely enable real-time, continuous monitoring of the contents, even when the boxes are removed from the freezer. A green indicator within a Cryoguard freezer box signals that the material within the box is not thermally compromised. The ability to identify freezer boxes whose contents are not thermally compromised enables personnel to “rescue” the material that is still safe to use after power failures and periods of coolant depletion.

Cryoguard indicators currently ensure the quality of cord blood, bone grafts, tissue samples, vaccines, sperm, embryos, eggs, adhesives and many other materials that are stored or shipped at temperatures from ‑65°C down to ‑196°C.

Cryoguard Corporation’s customers include blood, bone, sperm, egg and stem cell banks, clinical laboratories, research laboratories, fertility centers, veterinary clinics, vaccine manufacturers, adhesive manufacturers, and aerospace facilities.www.cryoguard.com

![]()